Tunneling Systems and Machine Technology for Tysons Corner, Dulles Corridor Metrorail Project

The Dulles Corridor Metrorail Project is a 5.25 billion Dollar project that is being built to create a high-capacity local traffic system in the Dulles Corridor near Washington D.C. and to reduce traffic congestion in the region. The project is owned by the Metropolitan Washington Airports Authority (MWAA) and includes the extension of Washington D.C.’s Metrorail System by 37km (23mi) to Dulles airport.

The work is divided into two phases. Phase 1 is the construction of an 18.8km (11.7mi) section from East Falls Church to Wiehle Avenue and includes four stations: Tysons Corner, Tysons Central 123 and 7 as well as Tysons West. Construction began in March 2009 and is scheduled for completion in 2013. Phase 2 includes the extension from Wiehle Avenue to Ashburn in the eastern part of Loudoun County. With this alignment, Reston’s city center, Dulles Airport and Route 606 will be closely linked to Dulles Corridor.

The hills in the Tysons Corner area through which the tunnel passes consist of mica schist that contains large amounts of quartz, phyllonite, gneiss and graywacke. Furthermore, gravel-like deposits and silt were found in the area of the planned tunnel alignment. Due to the difficult geological conditions and the very shallow soil cover in some areas, advance work was carried out mechanically using excavators and a shotcrete lining support in accordance with the principles of the New Austrian Tunneling Method (NATM).

For the construction of the 510m long double tube tunnel, DSI Underground Systems, USA and DSI Austria supplied a large amount of innovative products and systems as well as comprehensive site support services. DSI Underground Systems, USA’s scope included the supply of technical equipment such as Hany Mixers and injection pumps, breathing gear as well as lubricants and accessories. Furthermore, DSI Underground Systems manufactured and supplied the necessary lattice girders and underground steel supports that ensure an immediate support of the tunnel wall in the excavation area and are entirely integrated in the shotcrete lining during installation.

In order to support the active work area at the heading, DSI Austria supplied the innovative ALWAG Systems AT-114 Pipe Umbrella pre-support system. As the soil cover above crown was only 2.13m (7ft) at the tunnel portal, a double injection pipe umbrella was installed by a conventional drill rig. The double pipe umbrella consisted of 57 self-drilling tubes in lengths of 17.35m (57ft). The center to center distance at the mouth was 0.5m (19.69") and the outer diameter was 114.3mm (4.5"). The installation procedure was finished by carrying out the grouting work with a special cement suspension. 12.8m (42ft) of tunnel were advanced in each pipe umbrella section. The remaining part of the pipe umbrella served as an abutment ahead of the face to transfer the loads during stress redistribution. A single pipe umbrella with 27 elements was enough for the sections further inside the tunnel that had a larger overburden. Casing tubes with a total length of 45km (28mi) were successfully installed in both tunnel tubes.

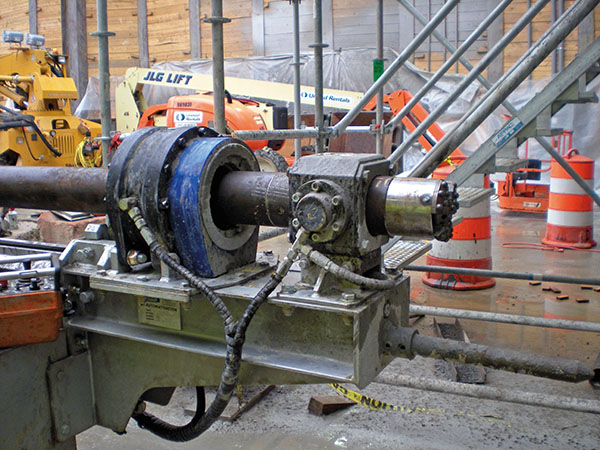

The use of two AT-Automation Units was another innovative solution for this project. They were assembled on a standard underground drilling rig (Atlas Copco EC218) that made the automated installation of the AT-Pipe Umbrella System possible. The AT-Automation Unit offers the following advantages:

time-saving pipe umbrella installation

cost reduction due to the faster installation process of a complete pipe umbrella

cost and time reduction thanks to a smaller saw tooth profile

higher occupational safety

reduction of staff requirement and downtime

As DTP’s Senior Mining Engineer Frank Jenkins comments, “In this technically challenging tunnel, we appreciated the close technical support, the hands-on mentality and the service DSI’s employees supported us with”.